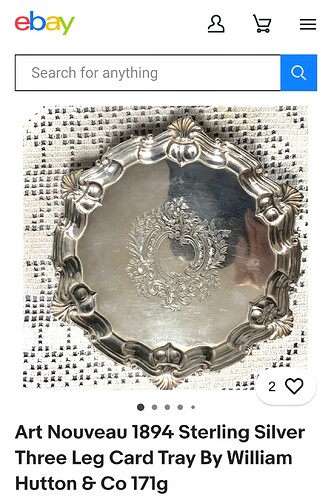

Hello, I’m really hoping someone can help with this issue… having done some homework, I know it’s a 1913 sterling silver card tray by William Hutton & Co (last photo is an example of how it should look). But this lovely tray is in a worrying condition, with an uneven, satin finish with some kind of corrosion bubbles under the surface!

The auction house I bought it from suggested the tray had been silverplated?! Does it look like it has been or has something else been done to it (painted)?

Why would someone do that and can it be restored? ![]()

![]()

![]()

I’ve been looking into electrochemical stripping, using a salt solution and electrodes to reverse the silverplating process… but this is always recommended for either removing silverplating off a base such as copper or gold plating off solid silver jewellery. My question is… can it be done to safely remove silverplating (if that’s what this is) off this sterling silver base??

Please help me out because the tray is too nice to stay in this tragic condition!

Cheers, Simon

It’s difficult to imagine what’s been done to this poor, defenseless card tray. There’s virtually never any reason to “meddle” with a piece of sterling silver, beyond some careful polishing.

My gut reaction is that it will cost more to have this tray properly restored than it’s worth. I’d insist that the auction house take it back, unless it was described as “horribly damaged.”

ETA: And there’s no way to remove silverplating from silver. The base layer is silver. The plating is silver. Anything that will remove the plating will also eat into the underlying sterling.

ETAETA: And there’s more bad news. If it’s been painted, most paint thinners are also too harsh for the silver, and will damage it.

Thanks Jeff, even though it’s bad news you’re delivering! ![]()

From the close up photos… do you think it’s silverplated or maybe spraypainted or something else? Have you ever come across this ugly look in the past??

I think it would be tough to produce that bad a finish using electroplating. I suspect some misguided soul decided that polishing off the tarnish was too much trouble, and that a quick coat of spray paint would do just as well.

If it’s a water-based paint, there’s some hope. Try warm soapy water and some gentle scrubbing. If that doesn’t help, try wiping on some mineral spirits. Or some gentle scrubbing with baking soda and vinegar. You might even try spraying some WD-40 on it, letting it sit for a few minutes, then wiping it off.

If it’s an oil-based paint, you may be faced with the prospect of selling the tray for scrap.

ETA: Either that, or just claim that it’s an example of repoussé. ![]()

Follow all Jeff’s excellent suggestions and if none of them work, take it to your friendly neighborhood silversmith and let him deal with it. It can all be buffed or rubbed out. Actually anybody with a buffing wheel can help.

This demonstrates the problem with buying off auctioneers relying on their photos.

This is secondhand silver rather than antique – yes I realize it is over a hundred years old – but still. So the value is in the melt. Which all else failing you can take it to the local smelter and get your money back.

CRWW

Thank you for your reply… I’ll try all options and just pray that it’s actually painted and not plated. Many thanks, Simon

I would need to see it but it does look as if something some off-gas has created air bubbles which have burst leaving what does look like “petals” of very thin possibly pure silver plated around the burst bubble.

The melting point of .925 silver or sterling silver, is around 893°C (1639.4°F. or slightly lower than the melting point of pure or .999 silver (plate) due to the presence of other metals, usually copper, in the alloy.

It would be great, given it is plated if you could heat to say 895° causing the plate to leave the .925 surface but since the sterling melts first, that seems to be the wrong way round.

Ironically if it is plated it will likely have been done to cover heat burn or bluing of the original sterling from exposure to extreme heat. Possibly a house fire. There are other ways of dealing with this problem. Better ways that do not involve plating.

I do know from my own experience with fire damaged silver that the heat allows the copper content of the heated item to absorb oxygen and it may well be that that is the absorbed gas that’s released under the plating as the item cools. Again, this is a discussion you should be having with a metallurgist.

In summary first determine if it is .999 plate over sterling. If so then determine what caused the bubbles coming out of the sterling but not going through the .999 silver — seems likely it would be a gas which does interact with copper and does not interact with silver and armed with that information figure out if you have to used friction( burnish or very fine sandpaper or both) to remove the .999 silver layer or if there is a chemical means using heat given the melt point differential or something else.

And that raises another matter. When this tray was made smiths were experimenting with mixing zinc, tin and even silicone with the copper to make a lighter colored, more silverly sterling silver.

If your tray contains one or more of these additional elements and one of them had held or attracted one or more gases while subject to fire burn heat and then that gas is released as the item cooled underneath the layer of solid silver, you again need to know about that additional element.

Cannot tell looking at it, but I have several late Vicky, early Edward VII items using this copper amalgam sometimes referred to as Britannia metal after the famous Britannia Mine producing zinc, copper, silver and gold out of a 230 km. seam which emerges at Britannia Beach just south of Squamish where Howe Sound cuts inland toward Whistler Mountain in BC.

I moored a steel steamship there one summer and despite the fact all my degausing equipment was turned off, so much copper and zinc was released into the sea water from the mine the ship emerged with no weed growth and plated with a mix of copper and zinc — exactly the solution Spanish galleons, carted silver from Peruvian mines used to plate metal attached to their wooden boats otherwise so susceptible to tropical bore worms.

You may had heard the expressions “Sea Green” and “Copper Bottomed” both British naval terms describing a person of solid reputation and uncorrupted.

CRWW

Thank you for a most detailed and interesting reply… from your explanation, the fire damage theory does make sense. And I never knew about the origins of the name Britannia Metal… very enlightening!

And you don’t think my initial hope of reverse-electroplating (in a salt solution) will work? The reason I was hopeful was because, although it’s used to remove silver plating off copper/steel base metals, it is also used to remove gold plating off silver jewellery (without damaging the silver). Does this make sense and could it work on silver plating on sterling silver?? Any insights would be much appreciated!

Many thanks, Simon

Think about this a bit more. Sterling silver is almost pure silver. Silver plating is almost pure silver (slightly more pure than sterling). What chemical process do you imagine could distinguish between the two? ![]()

Quite right, Jeff… I was just hoping the plating removal was more to do with the original electroplating binding process and not the actual metals involved… like removing gold plating off solid silver? But I guess I was just clutching at straws and some strong wishful thinking!! ![]()

![]()